There is no doubt that manufacturing industry is currently being at the stage of constant development. In addition to outstanding technological accomplishments and innovative solutions, the manufacturing evolution shifts existing industrial and market composition. Another shift happens regarding manufacturer mindset: here changes relate to rebuilding an outdated approach to planning, projecting and operating. This may be considered as a manufacturing revolution, sometimes obstructed by supposed simplicity, but summed up in one particular word: cohesion.

According to LNS Research survey on manufacturing operations management, two major challenges faced by respondents relate to lack of alliance across departments and inconsistency of data sources. Those issues become particularly crucial for modern manufacturers, who aim to maintain flexibility and gain the ability to adapt to market demand, maximizing efficiency and profit at the same time. To succeed in our century of rapid changes, manufacturing planning managers have to integrate suppliers, developers and other manufacturing assets into one single system. With that, system integrators have to be highly aware of the impact their offers have on this assets coercion, while planning managers are expected to continuously improve ways of communication and collaboration with all the parties involved in the process of planning.

Thankfully, there are tools allowing experts from different fields to get a clear understanding of each other, hence building strong team communication and reducing time of initiatives implementation. Visualization appears to be one of the most prominent of them.

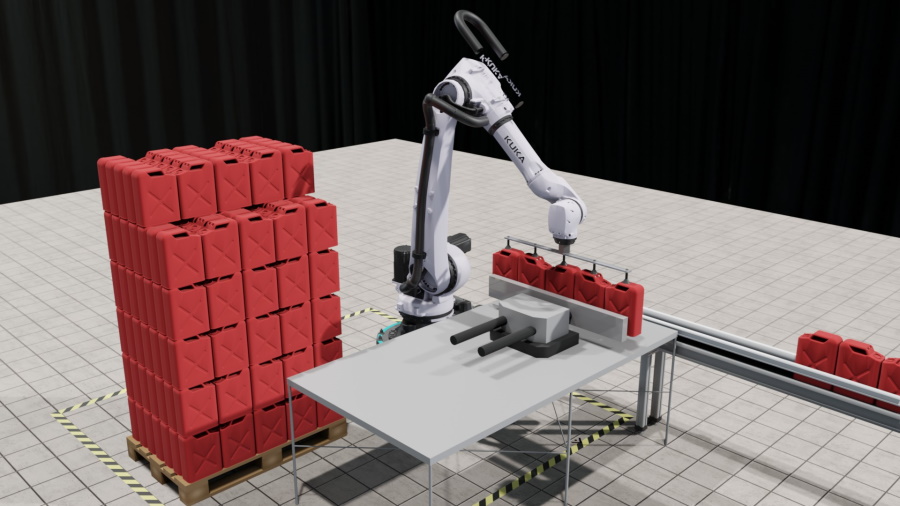

For the last several years’ visualization technology was combined with simulation modeling technology and internet and turned into 3D simulation technology of modeling, optimization and product management. This technology includes various input sources such as production plans, manufacturing processes, CAD geometries, CAM software, etc. and creates the precise visual representation and simulation of those by using manufacturing specifics of each component.

In other words, those simulations help the planning department to create an accurate representation of manufacturing environment and assess the effect of their decision and implemented changes on production layout and efficiency. With that, visualization plays a crucial role in reducing the risk of neglecting mistakes in planning and projecting as well as giving stakeholders ability to participate in those processes.

Consider the case in which a client company had missed a goods delivery and hence lost more than 1 $ mln. due to a miscalculation in planning Excel file and mistake omission. If this miscalculation is taken into account and later applied to the following manufacturing value chain, significant efficiency and output reduction entail with. In this example only one part of a toolkit for planning, i.e. an ordinary excel table, has brought significant losses due to its inability to precisely account the spatial aspect. Even though it was impossible to capture this aspect in Excel, it would have been evident with the use of 3D manufacturing simulation technology.

It becomes clear that system integrators and planning managers, who uses comprehensive visualization during the planning process, reduce the risk of major mistakes and omissions. Whеn disparate tools are used on certain planning stages only, vital details can be easily overlooked or missed, for example spatial features of robots, equipment or processes. 3D manufacturing simulation technology combines disparate data sources and helps to visualize changes due to the decisions made in a way to make potential mistakes visible before they become real. Besides that, one of the main visualization advantages is that it allows to significantly improve communication and collaboration at all stages of the planning process.

In the 21st century the planning process has become more sophisticated and complex. It now incorporates a wide range of participants, from the marketing and sales teams with process engineers working with the integrator, to quality control engineers and financial analysts from manufacturer’s side – all of them have a personal perception of processes and make a contribution of varying degree. Modern visualization technologies are crucial for every part included in manufacturing and planning processes in terms of faster networking, simplified understanding of dynamic processes and visible influence of decisions made. It allows everyone to participate with the higher efficiency, making complex visualization necessary for both system integrators and planning managers to increase cooperation quality.