What is digital twin?

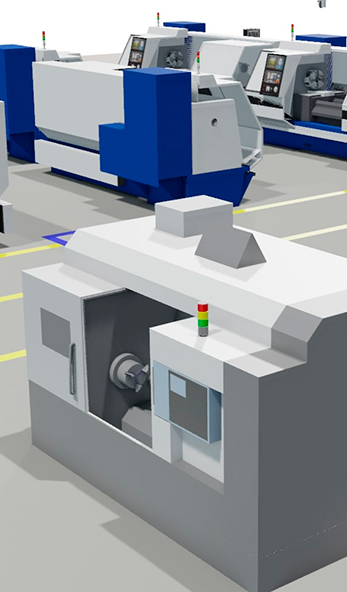

Digital twin is an interactive simulation model of a real production site.

Digital twin is an interactive simulation model of a real production site.

Digital twin is completely identical in terms of technical characteristics and production indicators to real industrial / logistics facilities, processes, operations performed and the behavior of physical objects in the conditions of real business activities of companies, external environmental influences.

Digital twin exists and can be used at all stages of the life cycle of technological processes. Which means that digital twin can be created for already existing facilities or the ones that are at the design stage.

What is digital twin used for?

Digital twin is a helpful tool for:

Digital twin is a helpful tool for:

- Simulation modeling

Simulation modeling is a tool for production optimization: in digital twin you can run a simulation and get the understanding of how production is working. Also you can gather production data for analysis.

This way it is possible to plan and check the improvements of production without making any drastic mistakes in reality.

- Virtual commissioning

Digital twin of your production site can be connected to the control systems. This way you can make sure that the system is functioning efficiently and is fulfills all the requirements before physical execution.

- Analytics & Optimization

In digital twin you can gather all production analytical data and then easily export it to share your results or investigate possible ways to optimize production.

What benefits you can gain from digital twin?

- Clear vision of all production sites and processes

- Improvement of production efficiency

- No more trial-and-error method

- Rational use of production space

- Fast and precise commissioning

Check out relevant online trainings in Digital Engineering!